Input

As it is known, as well as the selection of the cables used to transmit energy, the selection of the right cable accessories and cable accessory compatibility are vital in the connections made. What should be considered when choosing cable lugs that enable direct connection to many electrical applications?

What is a Cable Lug?

Cable lugs, also known as "connectors" or "anchors" according to industrial terminology, are cable accessories designed to provide direct connection to many electrical applications and to facilitate maintenance, repair, assembly and disassembly. The most common example is battery connection applications used to feed the electrical components of motor vehicles.

Usage Patterns

Cable lugs are used where there must be a permanent connection and where it is inconvenient to apply a direct connection. Depending on the way they are used, the methods of application may also vary. According to the type of shoe to be connected, soldering or welding is made. The attachment end of the shoe is then connected by means of a bolt, screw or clip by clamping it to the connection point with an exact matching terminal. The most commonly used metal in shoes produced in many sizes and with different metal materials is copper. Fork or "U" shaped lugs, for screw terminals; closed ring or "O" type shoes for bolted applications; pin or flat handle shoes are used for compression or knife-tipped terminals. Cable lugs are also used to reduce the cable size as they can connect the thicker section cable to a smaller sized connector.

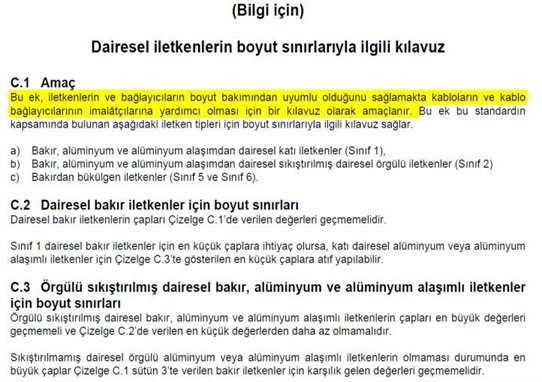

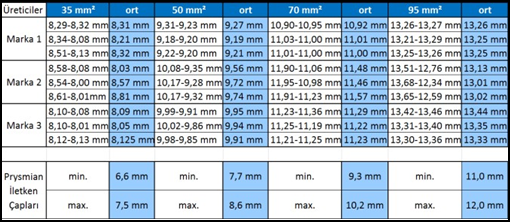

Shoe and Cable Compatibility One of the first and simultaneously most important stages of a cable design is conductor design. The most common standard for the design of conductors is IEC 60228. When designing and choosing a conductor, the geometric size and cross section of the conductor are very important; however, the most important parameter is not the geometric cross-section, but the electrical cross-section. This is achieved by the maximum direct current conductor resistance given for a length of 1km at 20 ⁰C. While the standards set the maximum conductor resistance requirement for the electrical section, they did not set a requirement for the geometric section, but gave the geometric diameter range to be information and guidance. The standard used by cable manufacturers in Turkey as the "Turkish Standard" for conductors is TS EN 60228: 2007.

This example also applies to other circular conductors. It is possible to see the tables containing the diameter information of other conductor classes in the annexes of TS EN 60228: 2007 standard.

As Türk Prysmian Kablo, our cable and conductor designs comply with both the "maximum direct current conductor resistance given for 1km length at 20 ⁰C" criterion determined by the standards and the "largest and smallest diameter" limits given as a guide.

However, in order to shed light on the comments about the nonconformities from the market and the questions posed to us, three of the cable shoes designed for four different sections (35, 50, 70 and 95 mm²) from three different shoe manufacturers were tested. It is evident in our test results that our conductors are fully compatible with each correctly produced shoe sample and the right compression.

Consequences of Improper Connection

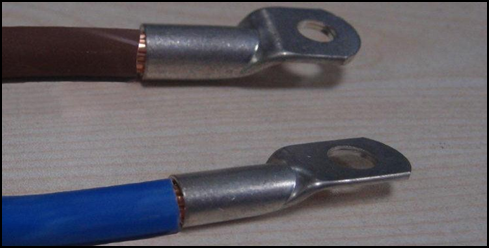

The necessity of the cable and shoe materials to be connected to comply with the standards is not an open issue open to discussion, and the correct terminal and connection method is perhaps the most important issue to be considered in terms of both the longevity of the system to be installed and the safety of life and property. Even if the right materials are selected and used, it is not even possible to encounter undesirable consequences due to the faulty connection to be made. One of the most common mistakes is to squeeze excessively. With excessive tightening process, the conductor at the connection point can be crushed and damaged. Since wire breaks may occur due to vibration, bending, etc. over time, the electrical resistance of the conductor will increase. Accordingly, overheating may occur. If overheating exceeds the limit values of the polymeric material used in cable insulation, it can disrupt the chemical properties of the polymeric material and result in fire.

The way to prevent errors is to use a hydraulic compression apparatus and have it calibrated before the period recommended by the tool manufacturer has passed. Another mistake is that a shoe is not selected in the section appropriate to the conductor section of the cable to be connected. If the shoe is selected larger than the required section, there may not be a desired level of coupling between the shoe and the contact surface of the cable conductor. As a result, with the arcs that may form in the gaps at the connection point, it may damage the polymeric material and cause fire. The way to prevent such situations; is to choose the right materials in accordance with the standards and make the right connection.

As Türk Prysmian Kablo, we continue to share our efforts to raise awareness of society and users. Let us not forget that the studies we carry out and the systems we establish will shed light on the generations after us.