Input

What is partial discharge, also defined as electrical partial discharge? Can these physical damages, which occur in a short or long time and even reach destructive levels in medium voltage and high voltage equipment, be prevented by monitoring and timely detection? Let's try to understand the root causes, types, detailed analyzes, tests, all other effects and consequences, as well as partial discharge.

What is Electrical Partial Discharge?

Electrical partial discharge is an electrical discharge or spark caused by the inability to form a complete bridge due to gaps in the structure of the dielectric material between two conductive electrodes or problems in its continuity.

According to its definition in IEC 60270; is the electrical discharge that occurs between conductors by only partially exceeding the insulation adjacent or discrete to the conductor. That is, it is the partial deterioration in the insulating material between the two active conductors.

Where and How Does It Occur?

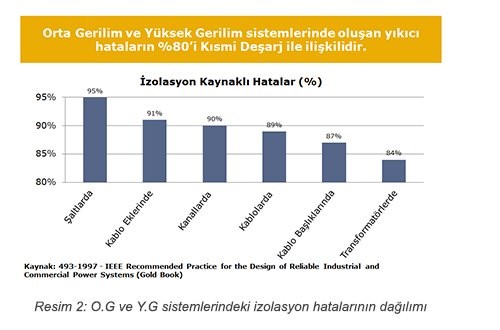

According to the research conducted by IEEE; A large proportion (80%) of the catastrophic errors that occur in medium-voltage and high-voltage systems are due to electrical partial discharge. (Image 2)

Electrical partial discharge can occur wherever there is an electric field strong enough to deform the dielectric material (switchgear, ducts, cables, cable headers, cable inserts, transformers).

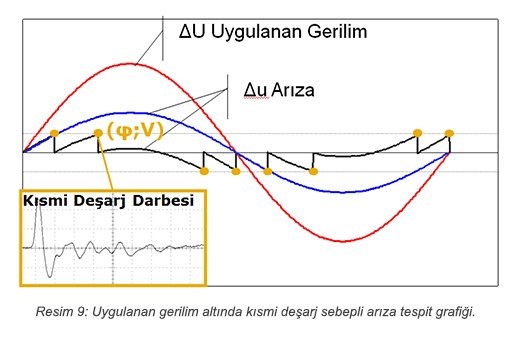

It is usually seen in the form of pulses of less than 1 microsecond. Although the pulses are very short-lived, the energy generated during the impact is strong enough to cause the dielectric material surrounding the conductor to deteriorate, and if left unchecked, to result in insulation errors.

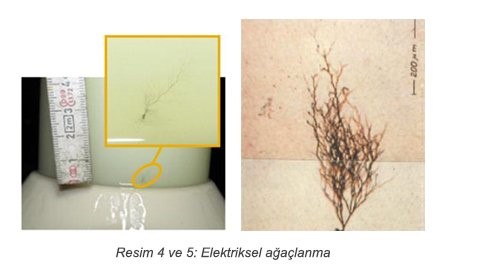

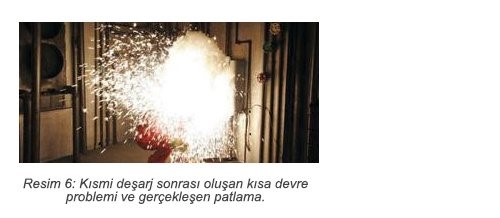

Electrical partial discharge may occur due to aging-induced deterioration, thermal or excessive electrical stresses, improper installations, faulty workmanship or improper designs even under normal operating conditions in devices and materials operating with high voltage or carrying high voltage. Progression and growth in dielectric material (electrical afforestation; As seen in Figures 4 and 5), the result can be sufficiently weakened and result in an interphase or phase-to-ground short circuit in 3-phase systems.

As it is known, some electrical partial discharges are extremely dangerous for the health of the insulation and therefore of the total system (example: polymeric cables and accessories), while corona events that occur at open and sharp points in high-voltage overhead lines or electrical partial discharges on the outer surface of the cable termination ends used in the open are relatively more dangerous.

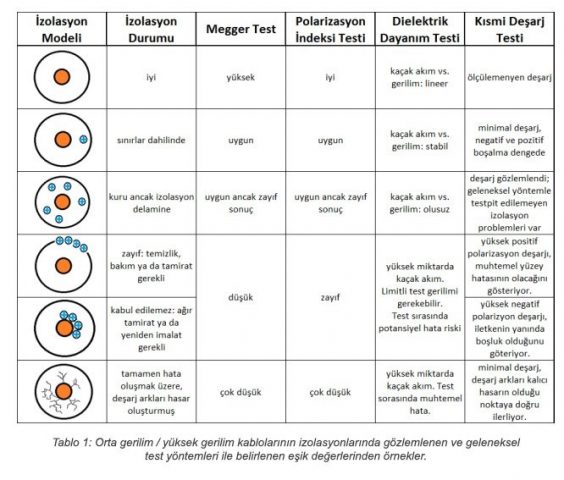

In some cases, deteriorated insulation structures successfully pass the voltage insulation test. Although cables and accessories are tested in much more stringent conditions above operating voltages, the best method of understanding whether the insulation structure is healthy is the partial discharge test.

Partial Discharge Error Detection

Threshold values;

During the partial discharge event, many types of energy (electromagnetic, acoustic, thermal, and light energies) are released. The partial discharge event can be detected with these energies and the test methods of the relevant energy type.

Electromagnetic Method

During the partial discharge event, electromagnetic (radio) wave propagation occurs from the part of the discharge. These waves cause current to be inducted in the metal housing. Due to the high frequency of the pulses of partial discharge that occur, the impedance of the grounded metal is large enough to create small voltages. This phenomenon was discovered in the 1980s and is now known as Transient Earth Voltages (TEV). Detection occurs through contact of a capacitive probe to the surface of the metal in the shape of a hand detector. TEV is an established method to detect partial discharge that occurs inside the insulation. Although it is mostly 200 MHz, the frequency of the electromagnetic wave from partial discharge can be more than 1 GHz. This energy can be detected using Ultra High Frequency (UHF) equipment. Multiple antennas can detect the location of the partial discharge source with the "Time-of-Flight" technique.

Acoustic Method

In both audible and ultrasonic ranges, the partial discharge event on the insulator's surface causes a sudden expansion of the surrounding air, which in turn creates a pressure wave. The sound coming in the audible range is similar to the sound coming from a piece of meat fried in oil on the pan. Ultrasonic is a sound wave of 20kHz. Detection is done with the help of a sensitive microphone tuned to 20kHz and is heard through a headset, converted into a sound of audible frequency. This technique is very useful when there is a range inside the metal housing through which sound energy can go out.

Thermal Method

During the partial discharge event, hot spots are formed due to the high current density in the part where the discharge is. It is possible to detect it by thermal imaging method. However, since most high-voltage elements are metal coated, it is difficult to reach hot spots by thermal method.

For this reason, thermal imaging is often impractical.

Beam Method

During the partial discharge event, due to the ionization of electrons and the recombination process, the photons are activated. The light intensity depends mainly on the size of the discharge and the insulation medium. During this event, the spectrum of light can be wide, from the visible range to the infrared. During the partial discharge in the air, nitrogen abundance prevails. As a result, 90% of the optical energy is generated in the ultraviolet region, while some of it is formed in the visible range in the dark environment. Of course, in order for its detection to be possible, the equipment with partial discharge must be in sight.

Prysmian Group's Groundbreaking Technologies on Partial Discharge Diagnostics

Pry-Cam

Designed for instantaneous partial discharge measurements. Easy, fast and reliable with its portable and wireless design; With patented electromagnetic sensitivity technology, it performs advanced partial discharge pulse modeling. Thanks to its galvanic insulation, it provides maximum safety for the operator and does not need to turn off the system because it measures online. It also provides testing flexibility by measuring many pieces of equipment on the same day.

Pry-Glass Grids

It is fixed to the system and allows partial discharge and continuous monitoring of the temperature.

It has a sensitive and advanced diagnostic system. It is fixed to the system and offers web-based remote monitoring. Just like Pry-Cam, it has galvanic isolation and performs advanced partial discharge pulse modeling.

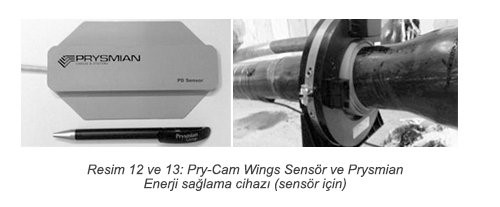

Pry-Cam Wings Sensor

It is the sensor that provides measurement of temperature and partial discharge parameters on the equipment to be installed.

It is adhered to every desired device and makes easy and fast measurements. If it cannot provide the energy it needs to work from the plant where it is installed, it can easily provide it with the Prysmian Harvesting Device.

DLog

It offers remote monitoring of analog signals (such as temperature, pressure, current, voltage).

It has 4 inputs for monitoring analog signals. It can make measurements at any scheduled time. It has a web-based interface for remote monitoring.

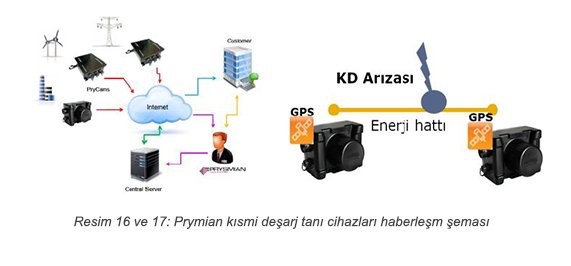

All partial discharge measurement technologies from the Prysmian Group can be conveniently used to prevent errors in critical parts. Again, in all their products, they do not need to de-energize the system to make measurements. It stores the measurement results with instant or continuous monitoring and allows them to be used and evaluated at any time. If desired, the two devices can communicate with each other via satellites.

As Prysmian Group, we continue to lead the industry not only in cable but also in cable systems. With our groundbreaking partial discharge measurement technologies, we continue to work for the healthy operation and continuity of your systems.