Yılmaz Özcan, EatonElectric Turkey Country Manager

PLC or control relays?

A few years ago, the answer to this question was obvious. In terms of functionality, while more powerful PLCs offered more possibilities, they were also more costly. With their ever-increasing capacity, control relays offer an alternative to moderately complex industrial applications. As Eaton sees in the case of the easyE4 relay, this is not just because of affordability.

In the wake of the Industrial Internet of Things (IIoT), the technical characteristics of key components in automation solutions have become even more complex. Ideally, whether it is a question of designing a new installation, renewing an old installation or upgrading an existing machine to a higher model, or implementing an advanced building automation system; these components are expected to take full advantage of the latest developments in digitalization so that they are not affected by future changes.

When it comes to the communication of machines and devices over the digital network and the data they provide, programmable logic controllers (PLCs) are the first choice that comes to mind. Perhaps, users resort to this way due to their habits. In fact, for a long time, control relays were seen as a cost-effective alternative to mechanical relays. Despite the fact that control relays have been successfully used in industrial projects and building automation projects for many years, this perception has not changed. However, when it came to the addition of new value-added functions such as condition monitoring, predictive and remote maintenance or smart building processes, control relays were not an ideal option.

However, this situation is changing rapidly. The distinction between PLCs and control relays is gradually disappearing, as control relays bring with them advanced programming languages, loadable operating systems, cutting operations and functions such as real-time clock and timer.

Given the functionality and flexibility of the latest generation devices (e.g. Eaton's easyE4 relays), users can compare PLCs and control relays based on all selection criteria, including aspects of the Human Resources department, such as the qualifications of programmers, commissioning engineers and maintenance personnel, as well as the complexity of the current application, its future-proofness, functional scope and scalability.

Flexible Control for Small and Medium Machines

Flexible Control for Small and Medium Machines

Note: Only applies to complex applications where PLCs are the first tool of choice.

In all other areas, cost is the factor that separates the two separate automation concepts. Control relays often offer better options because the rules of the game have changed with digitalization and it is no longer just the cost of hardware that matters, but also the associated investments such as staff training.

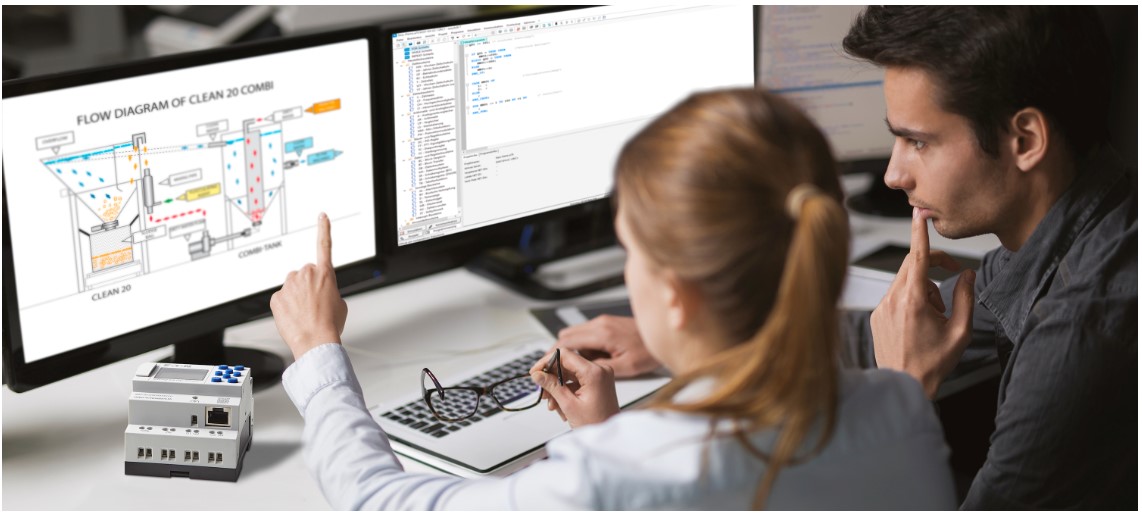

The technical specifications of the latest control relays and the IIoT-ready system architecture make it clear that these relays offer a solid alternative to PLCs. For example: To facilitate the collection and evaluation of status data at field level, each easyE4 base unit can be expanded by adding up to 11 digital and analogue modules or special inputs, which can be mixed without any limitations. The features of the application can thus then be individually adapted without the use of a PLC.

New Opportunities with Ethernet-Based System Architectures

For tasks such as production planning or predictive maintenance, networked structures are required to exchange machine and process data. In addition, Ethernet-based fieldbus systems such as Modbus TCP enable connection to the cloud and communication with system solutions. Each easyE4 device can serve as a Modbus TCP server. Modbus TCP clients, such as the Eaton XC300 PLC, can pull and process data from the easyE4 network. IoT gateways and routers can be easily integrated into Ethernet-based architectures, allowing you to connect any application to the cloud with the necessary access rights that ensure security.

Eaton Electric Turkey Country Manager Yılmaz Özcan;" When it comes to Industry 4.0, flexibility is of paramount importance and applications must be implemented accordingly. When it comes to flexibility, not only cost-effectiveness should be understood; it is also a determining factor of how future-oriented and adaptable the solution will be overall. In this regard, existing programming languages and functions play an important role. As companies increasingly rely on networked IIoT structures rather than relatively isolated and manufacturer-dependent solutions, the importance of these programming languages and functions will continue to grow. At the same time, it will also be possible to functionally integrate existing systems into new automation concepts." Said.

Programming Languages: The Choice Is Yours

Programming Languages: The Choice Is Yours

With modern programming tools, you can choose the programming language that works best for you. In the past, choosing a custom control relay model forced designers and users to adhere to a single proprietary programming language. The possibilities offered by this application were limited. Today, however, users can freely choose the programming language(s) of their choice. While users' habits can influence their decision whether to continue to benefit from the device-specific programming languages of previous models; Today's high-tech programming languages such as ladder diagram (LD or ladder diagram), function block diagram (FBD) or structured text (ST or structured text) offer users significantly more options. With easySoft V7 software, Eaton has developed a program that gives users the option to convert our previously familiar programming interface (EDP or easy device programming) into ladder diagram language or use any of the advanced programming methods for new projects.

As a result, manufacturer-defined traditional function blocks, which are easy to configure, stand out with application possibilities far beyond the functions offered by time relays and stairlight switches used in the past. It is even possible to implement more complex control and regulation systems with functions such as arithmetic modules, three-point control, data loggers and PID controllers.

Customized, User-Defined Function Blocks

Programming tools such as easysoftV7 allow users to write their own reusable and protected function blocks (UF). These function blocks bring many benefits: when programmed and tested, function blocks can be integrated into devices and systems in different expansion stages (as needed), while you can create the master program. This minimizes sources of failure, saves costs, and reduces testing and commissioning times. Moreover, the fact that the function blocks do not need to speak the same language as the main program also gives users more freedom.

Eaton's "easy" devices allow users to connect their apps with other technological approaches. However, achieving the full potential inherent in technology also requires a coherent visualization concept.

Although control relays cannot offer the same scope of functions as PLCs, the capacities of control relays are sufficient for many applications.

Screens have been seen as an integral part of control relays for a certain period of time. The screens are not only used to configure and program devices, but also show current operating values. With function blocks, parameters such as fill levels, temperature, quantity, run time or texts can be easily set in the programming tool. This represents a much cheaper alternative to human machine interfaces (HMIs), which are commonly used in PLC applications.

The integrated web server of the EasyE4 not only makes it possible to transfer local displays and function keys from the control panel to any mobile device (this is an important prerequisite for remote maintenance and distributed machine concepts), but also makes the devices future-proof. In other words, even when it comes to implementing moderately complex automation solutions, and the cost factor is also taken into account, control relays can compete nominally with a more powerful PLC.