Promising new space worth hundreds of millions of euros

Pooling its expertise in the field of mechanical engineering, Bosch offers companies plant equipment for the production of batteries from a single source, ranging from individual component and software solutions to complete assembly lines. Rolf Najork, member of Bosch's board of directors responsible for industrial technology, said: "We know batteries and how batteries should be produced like the palm of our hand." In entering this business, Bosch aims to increase vertical integration in mechanical engineering and achieve annual sales of around 250 million euros with battery production equipment by 2025. Using its production know-how in its own facilities, Bosch is launching full-scale production of 48-volt second-generation batteries at its factory in Eisenach, Germany. The company is investing around 70m euros this year to expand its local manufacturing operations.

Pooling its expertise in the field of mechanical engineering, Bosch offers companies plant equipment for the production of batteries from a single source, ranging from individual component and software solutions to complete assembly lines. Rolf Najork, member of Bosch's board of directors responsible for industrial technology, said: "We know batteries and how batteries should be produced like the palm of our hand." In entering this business, Bosch aims to increase vertical integration in mechanical engineering and achieve annual sales of around 250 million euros with battery production equipment by 2025. Using its production know-how in its own facilities, Bosch is launching full-scale production of 48-volt second-generation batteries at its factory in Eisenach, Germany. The company is investing around 70m euros this year to expand its local manufacturing operations.

The battery market is growing by 25 percent per year

The battery market is growing by 25 percent per year

Experts predict that lithium-ion battery demand will rise from 200 GWh in 2019 to over 2,000 GWh in 2030 (Source: BMWi, 2021). Currently, more than 60 percent of the demand comes from electromobility (Source: VDMA, 2020).

Bosch offers a portfolio of solutions ranging from 48-volt lightweight hybridization to fully electric drive systems and fuel cells. The company is experienced in battery development as well as e-bikes, power tools and kitchen appliances and has extensive manufacturing expertise.Bosch plans to use this know-how to meet the growing demand. "We assume that the global battery market will grow by 25 percent each year. Bosch is doing its part to meet this demand."

Webasto battery production is based on Bosch technology

Webasto battery production is based on Bosch technology

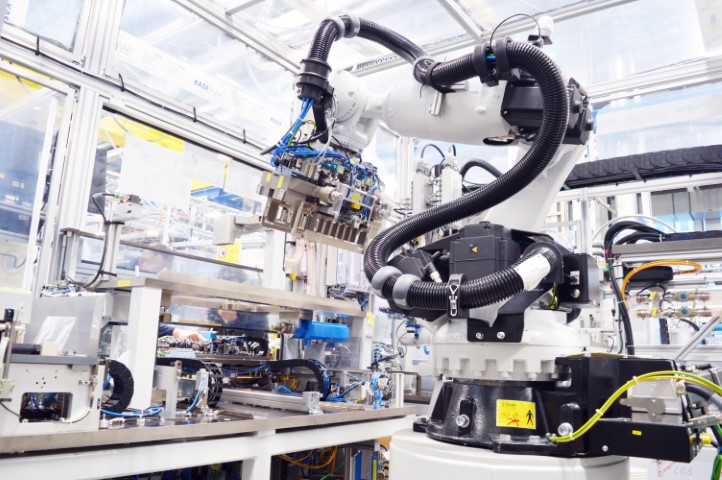

One of Bosch's pilot customers in this area is Webasto, which equips its battery factories with Bosch technology. Webasto, a leader in the production of battery packs, has been active in the field of electromobility since 2016 and focuses on battery systems for electric vehicles as well as high-voltage heaters and charging solutions. The battery, made at Webasto's plant in Schierling/Germany, serves as a prototype for new production facilities such as Dangjin in Korea. Bosch offers automatic assembly lines for welding and bonding battery cells. For this purpose, various functions of module manufacturing such as cell cleaning, package process along with access control, as well as special laser welding process and end-of-line quality control for quality assurance are incorporated. Thanks to the sophisticated line concept, no particle contamination occurs during the process. The robots automatically assemble the cell stacks in a two-step procedure consisting of distribution technology and laser welding. With the comprehensive safety concept, it is possible to establish the electrical connection of the battery module using a highly dynamic and precise laser welding process.

Bosch plants demonstrate impressive battery expertise

Bosch plants demonstrate impressive battery expertise

Bosch believes that industrial technology will also make progress in its own factories. At the company's Eisenach Plant, 48-volt batteries are produced for hybridization of passenger cars. Such batteries reduce urban fuel consumption and CO2 emissions by up to 15 percent, especially in vehicles with internal combustion engines. At Eisenach, the second generation is also moving to large-scale production. During production, more than 90 components are passed through more than 100 process steps. The electric 'tailwind' for bicycles comes from Hungary. Since 2015, Bosch's Miskolc Plant has been producing high-performance e-bike batteries that offer an extended product range and a long service life. To create a perfectly synchronized e-bike system, the batteries have to go through around 20 stages throughout the production process before the drive system and display are combined. Access control related to the cells, module and package assembly and battery management system integration are among these stages. Fully automated local production ensures high quality standards, maximum battery safety and a stable supply chain for e-bike manufacturers. Bosch will be exhibiting its electromobility solutions at the IAA Mobility in Munich from 7 to 12 September.

Bosch offers comprehensive services to manufacturers

Bosch offers comprehensive services to manufacturers

Bosch serves both as a general contractor in factory construction and as a supplier of individual components and software solutions. "As a leading IoT company and successful machine builder, we offer the opportunity to organize the factory of the future," Najork said. Bosch develops equipment, machinery, hardware and software to produce battery modules and battery packs made of cylindrical, prismatic or sac cells and used in electric vehicles. To firmly connect the cells together, the processes of tightening, welding and gluing are used. Depending on the requirements, Bosch can supply lines either partially or fully automatically. The company's portfolio also includes drive and control technologies, intelligent design manual workstations, production execution systems (MES) for production planning and software for connecting machines and systems.

SİZİN DÜŞÜNCELERİNİZ?

SİZİN DÜŞÜNCELERİNİZ?