What is a cable ferrule?

Cable ferrule is the connection consumable that attaches to the ends of flexible cables with cores, terminates the cable and provides a solid conductivity. After the ferrule is installed, the cable is connected to circuit elements such as circuit breakers, contactors, fuses.

Why use cable ferrule?

Thanks to its superior flexibility, long life and resistance to vibration, insulated core cable is an ideal choice for most electrical panels. These cables are formed by combining very thin copper wires and wrapping them with an insulating material. If the insulation material on the cable is stripped and tried to be connected to the terminal ends in this way, disintegration will occur at the cable ends. This will cause the cable to lose its strength and durability.

At the same time, if the multi-core cable is connected to the clamping without ferrule and current is passed over it, a short circuit may occur at the connection point due to the dissipation of the cable end and corrosion occurs over time. Since not every point of the disintegrated wire will touch the terminal blocks, the connection efficiency will also decrease.

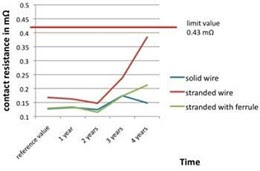

Corrosion refers to an increase in contact contact resistance. The greater the contact resistance, the higher the temperature inside the connection, leading to higher current. A contact resistance above 0.43 mΩ can cause loss of insulation, short circuits and burns inside the enclosure.

Using cable ferrule, the threaded flexible cable can be given a rigid cable durability at the entrance of the ports. Ferrules significantly simplify installation, increase safety and reduce the risk of costly panel failure.

The graph below shows the change of contact resistances of a single-core rigid cable (blue), a multi-core stripped cable (burgundy), and a multi-core stripped and ferrule cable (green) over time. As can be seen, the contact resistance of many cores using ferrule is almost equal to the resistance of a single-core rigid cable.

How should the cable ferrule be plugged?

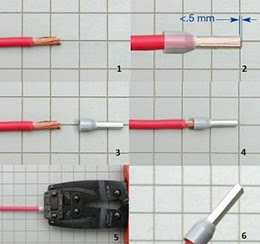

1-The cable should be cut properly without angling and damaging the vessels.The length of the cut should be made depending on the length of the ferrule and the outer diameter of the wire.

2-After the ferrule is installed, the conductor bundle should not hang out more than 0.5 mm.

3-Cable ends should be collected in such a way that they are not messed thinly

4-It should be placed in place so that there is no conductive wire outside the plastic ring.

5-Ferrule should be squeezed with the clamping apparatus

6-Then the strength of the prepared cable should be checked by pulling slightly.

Cable ferrule selection

1-Cross-section of the cable to be connected

2-Color

3-Ferrule dimensions

4-Whether it has an insulated or non-insulated head

5-Peeling or stripping length

6-Whether to make single or double connection (Two different cables can be connected to a single ferrule in some ferrule models)

7-International standards

SİZİN DÜŞÜNCELERİNİZ?

SİZİN DÜŞÜNCELERİNİZ?