No matter what type of application (Hospital, Datacenter, Residence, Military Facility, factory, etc.), it is essential to use RELIABLE POWER for the operation activities of the facility. When it comes time to purchase a generator set, it is very important to think about where the generator will be located and how it will work. If you think the generator will be located within a room/building, you should make sure that you comply with all generator room design requirements.

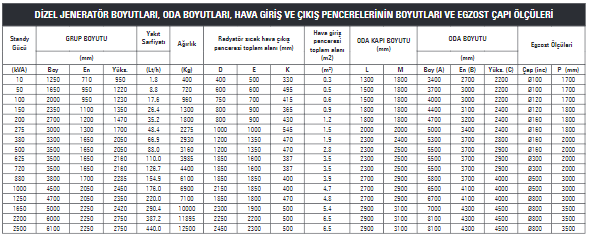

The space requirements for emergency generator sets are not at the top of an architect's building design list. Especially since the generators in large powers take up too much space, there are problems in providing the necessary space. At the beginning of a building/facility design, we recommend that the design of the building be carried out by consulting the experts in this field with the design requirements required for the healthy operation of the generator with its equipment.

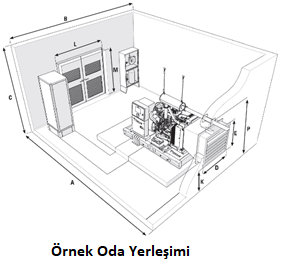

It is a whole with the generator and its equipment (control panel, fuel tank, exhaust silencer, etc.) and the design should be made by taking this integrity into consideration.

The generator room floor must be liquid-proof to prevent leaking oil, fuel or coolant from passing into the soil.

The generator room design must comply with the requirements of the ''Regulation on Fire Protection of Buildings''.

The generator room should be clean, dry, well lit, airy, not excessively hot, smoke, oil vapor, engine exhaust fumes, etc. should not get into the room.

Insulation etc. materials to be used in the room should be selected in the non-combustible / flame conduction class.

The room floor and base should be designed taking into account the static and dynamic weight of the generator.

The door width/height of the generator room should be such that the generator and its equipment can be easily transported to the room.

Generator set equipment (Fuel tank, silencer, etc.) should be located close to the generator. Otherwise the pressure losses and back pressure will increase.

The control panel must be positioned correctly for easy use by maintenance/operation personnel.

Sufficient space should be available for periodic maintenance.

There must be an emergency escape gate and there must be no equipment (cable tray, fuel pipe) to prevent the escape of personnel on the emergency escape route.

There should be a three-phase/single-phase socket, water line and, if possible, an air line for ease of maintenance/operation in the room.

If the daily fuel tank of the generator is of the external type, the fuel piping must be fixed installation up to the generator and the connection from this fixed installation to the engine must be made with a flexible fuel hose so that the engine vibration is not transmitted to the installation. We recommend that the fuel installation be installed through a channel through the ground.

Power and control cables must also be installed in a separate channel. Since the generator will oscillate on the horizontal axis in cases such as start, first step loading and emergency stop, the power cable to be connected should be connected by leaving a certain amount of space.

Generator room ventilation has two main purposes; To provide an environment for the generator to work correctly so that its life is not shortened and the maintenance / operation personnel can work comfortably.

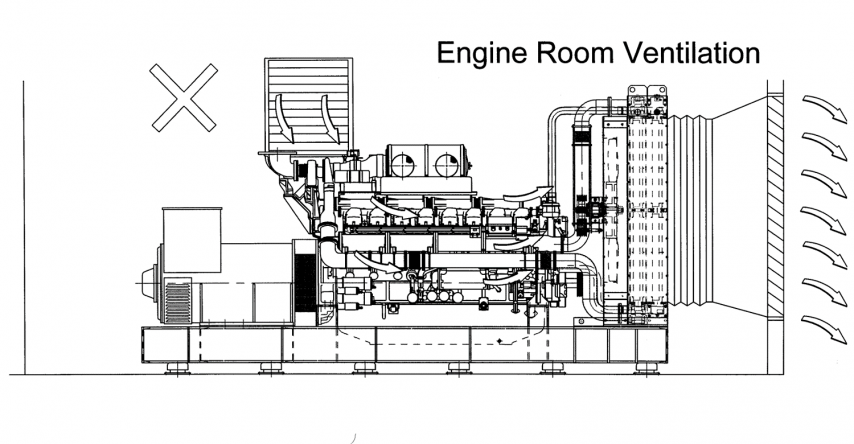

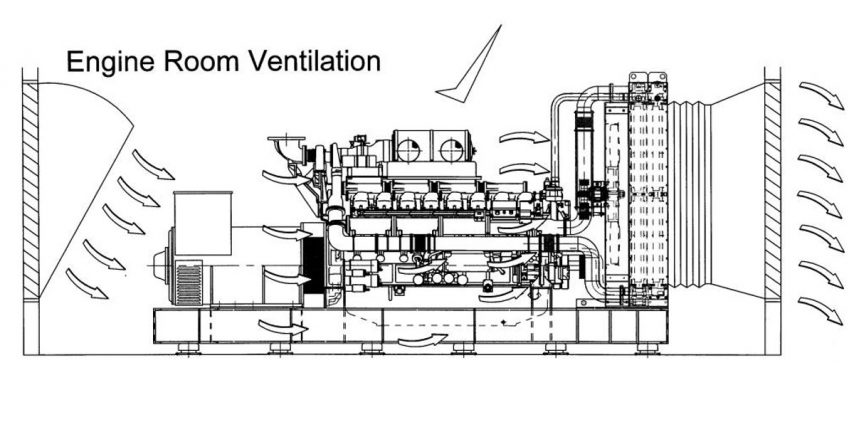

In the generator room, after the start-up, an air circulation starts due to the radiator fan, fresh air enters from the vent behind the alternator, passes over the engine and alternator and cools the engine body to a certain degree, the heated air is thrown into the atmosphere from the hot air shot vent in front of the radiator.

In order for ventilation to be carried out efficiently, the air suction/shot opening must be of appropriate dimensions.

Shutters should be made on the windows to protect the air openings. Shutter fins should have openings that do not interfere with air circulation. Otherwise, back pressure is created and the generator is caused to heat up. The biggest mistake made in this regard is the use of the shutter fin structure similar to the culverts in the transformer rooms in the generator rooms.

Help should be obtained from the company where the generator set will be purchased about the size of the air suction / shot and the shutter detail.

A hood should be used between the radiator and the air shot window. The connection between this hood and the radiator must be used to prevent the transmission of generator set vibration to the building by using materials such as tent cloth/canvas fabric.

For rooms where ventilation is troublesome, ventilation flow analysis should be carried out and it should be analyzed that ventilation can be done properly.

The engine sump ventilation must be connected to the radiator by means of a hose. In this way, oil vapor should be easily expelled from the room to the external environment. Precautions should be taken so that no rain enters the sump ventilation line.

In applications with gas fire extinguishing system, automatic shutters should be used.

The fuel tank and capacity must comply with the requirements of the ''Regulation on Fire Protection of Buildings''.

The fuel tank must be installed in a reinforced concrete or metal overflow pool.

Tank ventilation should be moved outside the building or, if the tank is to be installed in a separate room, there should be an ventilation vent in the tank room.

The fuel piping should be far from the hot zones of the generator and the exhaust line.

Black steel pipe should be used in fuel installations. Metal pipes such as galvanizing, zinc alloy, etc., which have a chemical reaction with fuel, should not be used. Otherwise, impurities formed by the chemical reaction can clog the fuel filter.

In places where there is fuel, sparks, flames and smoking should not be allowed. Warning labels must be installed in this regard.

Heaters should be used for the fuel system installed in cold environments. The tank and pipes must be protected with insulating materials.

How and how the fuel tank filling will be done should be considered and designed during the room design.

The fuel tank and the generator should be preferred at the same elevation. If a different application is required, support should be obtained from the generator set manufacturer.

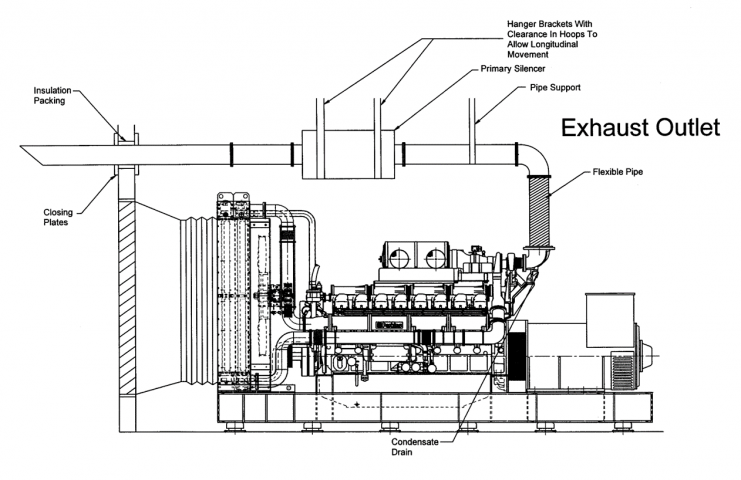

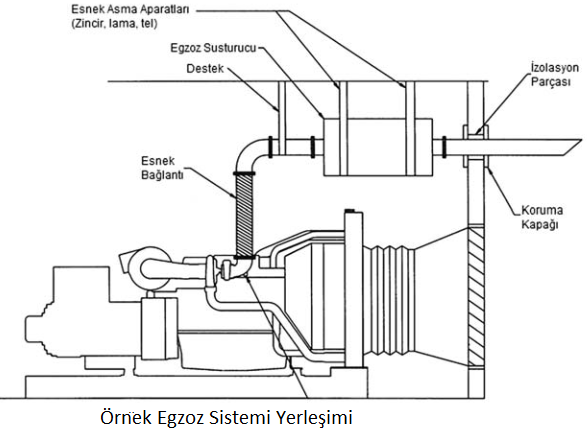

The exhaust system (muffler and pipes) is installed to reduce the noise emanating from the engine and to direct toxic exhaust gases to the appropriate areas.

Inhaling exhaust gases is a possible danger of death. The penetration of exhaust gas into the engine shortens engine life. For these reasons, it should be sealed until the exit point deemed appropriate.

The exhaust system must consist of flexible compensators, silencers and pipes that absorb vibrations and expansions.

Exhaust pipe brackets and mounting elements should be selected in accordance with the expansion with temperature.

When designing the exhaust system, the main objective should be not to create back pressure. In connection with the path to which it will go, the pipe diameter should not be narrowed and the correct diameter should be selected. For the exhaust pipe route, the road with the shortest and least rotation should be chosen.

A rain hat that moves with exhaust pressure should be used for use in vertical outlet exhaust pipes.

Insulation should be made to the exhaust pipe and silencer in the room. Otherwise, the exhaust temperature increases the temperature in the room, reducing the performance of the generator.

The direction and point of exhaust gas shot is very important. In the direction of the shot should not be settlement, plant and path. The prevailing wind direction must be taken into account.

Exhaust stand application can be made in places where there is a problem in hanging the exhaust silencer from the ceiling.

SİZİN DÜŞÜNCELERİNİZ?

SİZİN DÜŞÜNCELERİNİZ?